top of page

AX Molding Co., Ltd.

Specialized manufacturer of T-dies and feed blocks

We can handle a variety of applications, including high-precision thin film dies, sheet dies, and multi-layered products.

Tanzawa Techno Center (design, development, and manufacturing base)

0463-68-8223

FAX: 0463-57-8276

553-1 Soya, Hadano City, Kanagawa Prefecture, 257-0031

03-6424-7570

Head Office (Administrative and Accounting)

FAX 03-6424-4676

CINZA101, 2-8-2 Minami-Kamata, Ota-ku, Tokyo 144-0035

Reception hours: 8:30-17:30 (excluding weekends and holidays)

Sheet Die

Features of T-dies for sheets

T-dies for sheets have a lip gap of 1 mm or more. Thicknesses of around 1 to 5 mm are the norm, but thick sheets up to 20 mm can also be molded.

Sheets are often used in construction materials and automotive applications.

The lip gap is large, so the resin accumulates inside the T-die and can be extruded. Therefore, the resin residence time is long.

Choke bars are often used to adjust the internal flow rate. There are two types of choke bars: vertical and diagonal.

It is common to see replacement lips attached to accommodate different sheet thicknesses.

Lip adjustment bolts often use a hook type. When adjusting the lip, you can adjust it by pressing on a flat surface rather than just pressing on a single point, allowing for smooth lip adjustment.

The lip edge is rounded to about R0.2, making it easy to handle.

T-dies are often placed horizontally and ejected from the side, so jack bolts and stands can be placed under the T-die, making it easy to handle the equipment.T-dies for film are often ejected from the bottom, so they are often hung up, making them difficult to handle and requiring care.

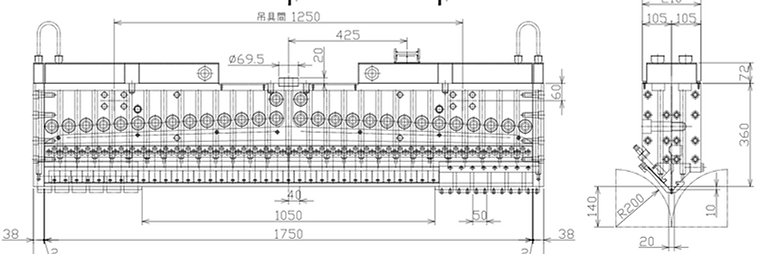

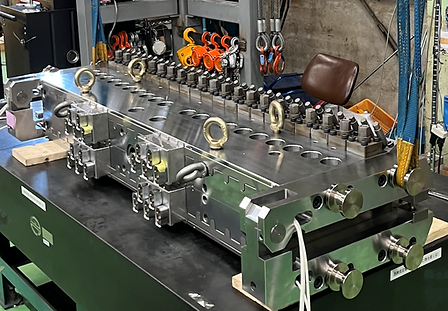

<T-die for sheets>

<Sheet die: special bending mechanism>

Special bending mechanism: For sheet dies, we have devised a way to increase the lip bending of the adjustment bolt to reduce the frequency of lip replacement and enable efficient production in response to the need to produce a wide variety of products in small lots. Bolt breakage, which often occurs at production sites, is caused by trying to forcefully adjust the bolt when making large changes to the lip bending, which puts stress on the bolt and causes it to break.

To mitigate this phenomenon, AXM has designed an ingenious bending mechanism.

<Bending section overview>

Adjustment bolt when free

Pull with the adjustment bolt

●A rotating axis is provided in the part, which absorbs tilt of the clip part and is designed to relieve stress on the bolt.

<Deckle die for sheets>

In addition to the choke bar and lip bending, inner and outer deckles can be installed to allow for precise adjustment of the sheet width to be produced, and the die can also be designed to accommodate different types of sheets to be produced without changing the die.

<Thick plate sheet die with choke bar>

Straight choke bar type

Diagonal chalk bar type

When the die needs to be compact

A structure is created that allows the flow path to be adjusted using a diagonal choke bar.

When molding raw materials that are prone to burning, it becomes necessary to disassemble and clean the die more frequently.This method is designed so that after the T-die is removed from the extruder, the bolts are removed and the die can be quickly opened in a hinged shape for cleaning.In order to maintain quality for our customers, we pay close attention to even the smallest details other than the flow path to supply T-dies that will satisfy our customers.

<Fishtail Die>

It is generally used with high-pressure T dies containing fillers or low-pressure T dies for foaming. In high-pressure T dies, filler-containing resins have high viscosity, so the resin does not flow easily to the sides. A fishtail die is an improvement over this, allowing the resin to flow not only to the center but also to the sides, with a gentle slope. Low-pressure T dies for foaming are molded with a gentle slope rather than a steep slope, so that resins such as those used for foaming will undergo a foaming reaction if pressure is applied suddenly, and so not much pressure is applied.

We have a wide range of manufacturing experience, from olefin-based sheet dies to engineering plastics and high-pressure dies containing fillers. We will use our design capabilities to help you solve your problems. We will also consult with you about any problems with your current equipment (T-dies). We look forward to hearing from you at any time.

bottom of page