top of page

AX Molding Co., Ltd.

Specialized manufacturer of T-dies and feed blocks

We can handle a variety of applications, including high-precision thin film dies, sheet dies, and multi-layered products.

Tanzawa Techno Center (design, development, and manufacturing base)

0463-68-8223

FAX: 0463-57-8276

553-1 Soya, Hadano City, Kanagawa Prefecture, 257-0031

03-6424-7570

Head Office (Administrative and Accounting)

FAX 03-6424-4676

CINZA101, 2-8-2 Minami-Kamata, Ota-ku, Tokyo 144-0035

Reception hours: 8:30-17:30 (excluding weekends and holidays)

Import business (sales of overseas-made equipment)

Our company also collaborates with equipment manufacturers overseas (in Asia).

We combine the functions of a trading company with engineering, and handle everything from determining equipment specifications to managing the production progress of overseas manufacturer equipment.

We provide one-stop service, including installation at the customer's factory.

Of course, we also provide thorough after-sales service after the equipment is installed. We are creating new solutions in collaboration with equipment manufacturers both in Japan and overseas.

⭐️The world's largest! Sheet forming equipment with a product width of 8m

Earthwork sheets support our daily lives and are essential for civil engineering infrastructure development.

In the Japanese market, 2-meter wide products are widely available. By increasing the sheet width, it is expected that the work efficiency of laying the sheet during ground improvement work will be greatly improved.

Why not consider starting a business that will become a pillar supporting the infrastructure of our country, a country prone to earthquakes?

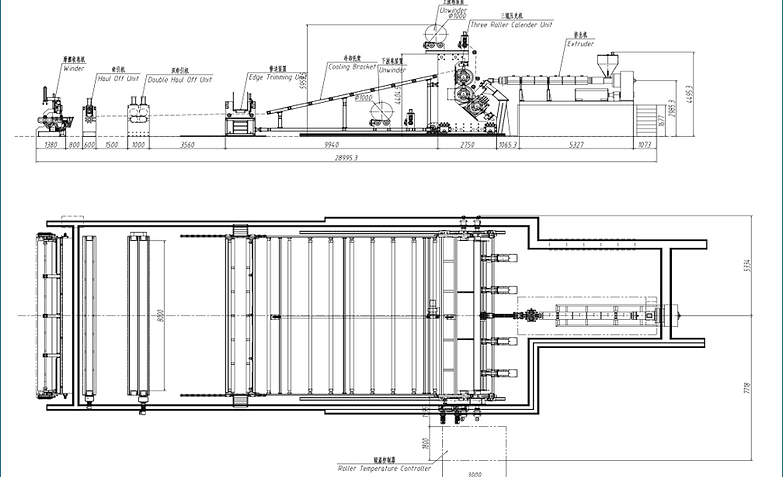

<Overall view of the device (for reference)>

.png)

A wide sheet forming line that can dominate the Japanese market.

<T8400 manual die>

<Complete set of thick plate molding/round bar molding (solidification molding) equipment>

<Fully automatic thick plate molding line compatible with PEEK (high-temperature engineering plastic)>

Round bar dies can also be made to order according to customer specifications.

We can accommodate short lead times from order to delivery.

Please rest assured that we will handle after-sales service!

<Small inflation molding device>

*No additional equipment required! Ready to operate immediately after connecting to power!

It is small and easy to handle, and is also suitable for test molding. It is ideal for sample development, new product development trials, film formation tests with new materials, etc.

This is the perfect device for laboratory equipment. No additional equipment is required (compressed air, cooling water, etc.), so test molding is possible immediately after connecting to a power source.

Price (basic specifications) 1.6 million yen/unit (excluding tax)

*Shipping charges will be charged separately.

*Optional options such as enlarging the screw diameter are also available.

bottom of page