top of page

AX Molding Co., Ltd.

Specialized manufacturer of T-dies and feed blocks

We can handle a variety of applications, including high-precision thin film dies, sheet dies, and multi-layered products.

Tanzawa Techno Center (design, development, and manufacturing base)

0463-68-8223

FAX: 0463-57-8276

553-1 Soya, Hadano City, Kanagawa Prefecture, 257-0031

03-6424-7570

Head Office (Administrative and Accounting)

FAX 03-6424-4676

CINZA101, 2-8-2 Minami-Kamata, Ota-ku, Tokyo 144-0035

Reception hours: 8:30-17:30 (excluding weekends and holidays)

Small conical molding device

(Nano Conic 20g )

What is Materials Informatics (MI)?

Several types of materials are mixed and kneaded in a short time (about 15 minutes) using a few grams at a time.With automation, more than 10 patterns of sheets can be formed in a day and each sheet is measured.In the future, AI will be used to quickly predict the material mixing ratio.

This time we have developed an ultra-compact extruder and roll forming machine.

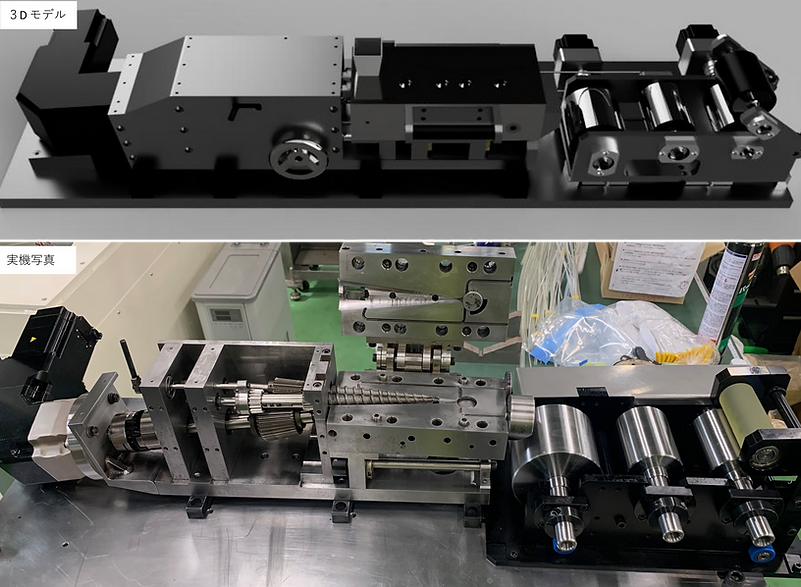

Equipment Drawing

Small Roll Forming Machine

Small raw material feeder

(Light powder can also be supplied by the screw)

Screw diameter 15mm, 20g per batch, screw rotation in the same direction/opposite direction, all in one unit

Patented Technology

100V power supply specification

Considering that it will be used for research purposes,

Compact and power supply improved so that it can be started with 100V power supply

It saves space and energy.

The actual machine is always installed in our company.

We also provide support for test use, tours, and rentals prior to implementation.

<Operation screen (PLC) in-house developed program>

Film formation with a small die head

This device can also be used to mold small amounts of pellets into films up to 50 mm wide.

We can make sheets from the raw materials you have developed using a very small amount of pellets.

You can also come to our company and borrow our machines. If the raw material requires high confidentiality, we will provide an enclosure so that only your researchers can carry out the molding. Please consider this option.

<Interlocking screws (same direction/opposite direction) Screws are created using a metal 3D printer>

Rotating in the same direction

Counter-rotation

This is the ideal equipment for research purposes. We also accept modifications to special specifications such as high temperature specifications.

We have the actual machine permanently installed in our factory, so please feel free to contact us or visit us.

bottom of page