top of page

AX Molding Co., Ltd.

Specialized manufacturer of T-dies and feed blocks

We can handle a variety of applications, including high-precision thin film dies, sheet dies, and multi-layered products.

Tanzawa Techno Center (design, development, and manufacturing base)

0463-68-8223

FAX: 0463-57-8276

553-1 Soya, Hadano City, Kanagawa Prefecture, 257-0031

03-6424-7570

Head Office (Administrative and Accounting)

FAX 03-6424-4676

CINZA101, 2-8-2 Minami-Kamata, Ota-ku, Tokyo 144-0035

Reception hours: 8:30-17:30 (excluding weekends and holidays)

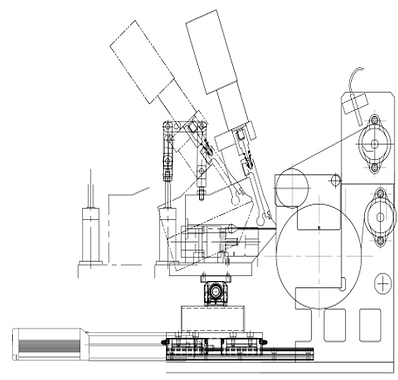

Intermittent coating device

<Small intermittent coater for lithium-ion battery/solar cell (perovskite) development>

In today's thin film market, there is an increasing demand for special films that have been given functionality through multi-layering, and then further enhancing their functionality through post-processing such as coating, vapor deposition, and chemical treatment of the film surface.

In particular, development of coatings for "new solar cells (perovskite solar cells)" is intensifying not only in Japan but also around the world.

Our company has engineers who combine elements of "T-die design," "coater die design," and "machine tool design." They are also involved in the manufacture of development equipment, making use of the flow analysis methods and lip structure know-how they have cultivated in the T-die field.

Small intermittent coating device (our in-house equipment) → *This device is also available for sale!

Slot die width 210mm

Roll surface length 250mm

Dry warm air heater (blow)

Coating method: Pressure tank type

(Die and roll face lengths can be customized)

The coating fluid is supplied to the slot die by pressurizing the fluid level in the tank using a pump. When stopping, the pressure on the pressurized tank side is released and the fluid supplied to the slot die side is instantly vacuumed using a vacuum pump, improving the breakability of the coating fluid (residual fluid on the die lip) and achieving intermittent, uniform coating.

However, when trying to apply the very low viscosity coating fluid seen today evenly, there was a concern that there would be a difference in coating thickness between the beginning and end of the coating.

<Possible issues when coating with a slot die>

Controlling the amount of coating when the coating liquid is supplied and when the supply is completed is extremely difficult, especially when it comes to coating an ultra-thin film.

1 Experience and track record of mobile coating equipment

2 Lip opening and closing using a motor die

We are developing design mechanisms that can improve this issue by making full use of our knowledge and experience.

Patented technology: Hybrid automatic adjustment lip die + T-die forward/backward moving device

<Front and rear moving unit model>

<Lip opening/closing + T-die moving type + intermittent coating>

1. At the coating fluid supply (coating) stage, the servo motor advances the T-die unit (controlling the clearance with the film)

2. Control the T-die lip gap. At the same time, move the T-die lip opening toward the machine (by swinging the angle).

3. At the end of intermittent coating, the die lip is closed (during vacuum application) to prevent excessive suction, reducing the time lag in the supply of the supply liquid when the next coating begins and allowing for intermittent production of a stable coating film.

In the production of perovskite solar cells, the crystallization of the perovskite layer (CaTiO3) is an issue, and there are questions about whether the winding method is better.

We have received information that there are still research topics to be investigated, such as whether cutting (Manyo style) is better or which method is better for establishing a mass production system.

For research and development equipment, we offer proposals for equipment that can meet a wide variety of needs.

We are particularly focusing on the slot die, which is the key to coating, and are conducting research and development activities.

Would you like to join us in developing new, value-added thin film by utilizing our T-die related technology?

Please feel free to contact us with any technical questions!

bottom of page