top of page

AX Molding Co., Ltd.

Specialized manufacturer of T-dies and feed blocks

We can handle a variety of applications, including high-precision thin film dies, sheet dies, and multi-layered products.

Tanzawa Techno Center (design, development, and manufacturing base)

0463-68-8223

FAX: 0463-57-8276

553-1 Soya, Hadano City, Kanagawa Prefecture, 257-0031

03-6424-7570

Head Office (Administrative and Accounting)

FAX 03-6424-4676

CINZA101, 2-8-2 Minami-Kamata, Ota-ku, Tokyo 144-0035

Reception hours: 8:30-17:30 (excluding weekends and holidays)

Automating manufacturing processes and utilizing VR technology (development)

Manufacturing automation & Utilization of VR technology (Development project)

We continue to take on the challenge of developing next-generation manufacturing processes that combine traditional artisanal techniques in extrusion molding with robotics/VR technology.

1. Development of manufacturing processes using robotic technology → Incorporation of robotic technology in dangerous work such as lip adjustment 2. "Safety education program," "Consideration before introducing equipment," "Experience of equipment operation in virtual space," and "Simplification of equipment manuals" using VR

<Automation of existing extrusion equipment>

T-die adjustment is done manually by humans

Robots take over the work

Early development testing/operational confirmation

Film Thickness Gauge (Traverse Type)

Robot arm adjusts

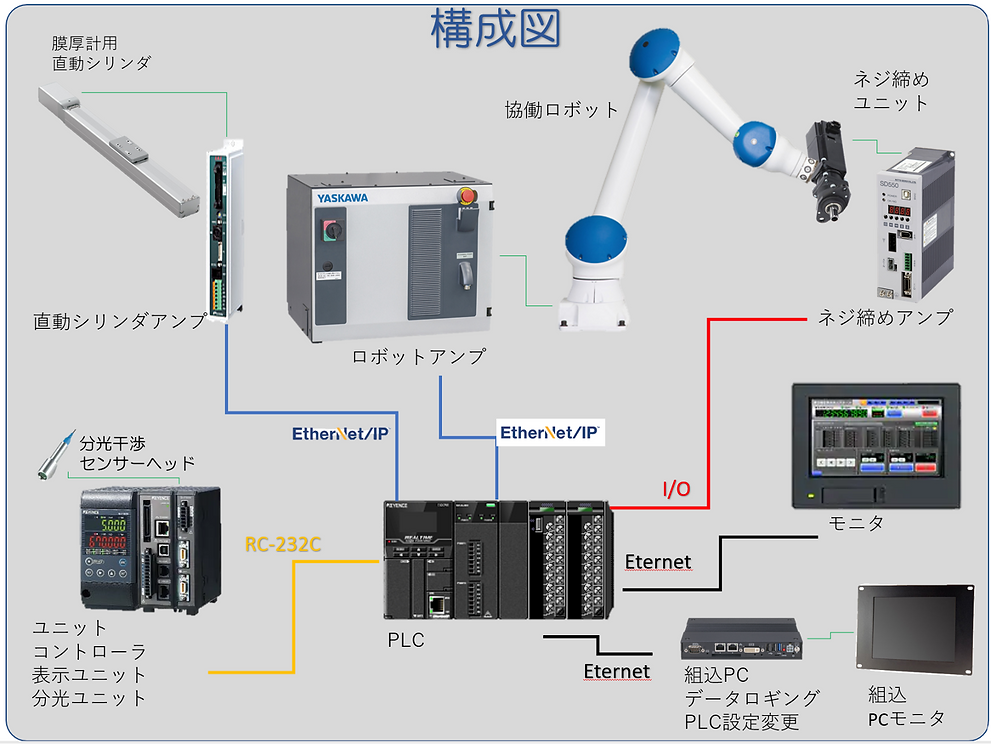

Test verification to automate dangerous operations on existing small extrusion equipment.

Operation algorithms, programs, work safety, and interlocking with film thickness gauges (lip adjustment) are realized in a compact machine.

Image of robot adjustment

Thickness measurement data read from our in-house developed film thickness meter is mapped to determine the amount of adjustment required (bolt rotation) and the areas that need adjustment.

We have created a system that allows the robot to automatically adjust the bolts using an automatic program.

This program allows us to build a system that can automate the user's manual dies.

<Application of VR technology>

We have developed software that utilizes VR goggles to enable training in machine operation, risk prediction, and film thickness adjustment methods in a virtual space. By combining this with robotics technology, we have developed a system that promotes intuitive learning in a virtual environment.

Real-space shaping device

After wearing goggles Film deposition in virtual space

No film formation occurs in real space

Virtual space Red areas are where the film is thick

In-house machine operation training using actual test resin reduces raw material loss and machine operating power costs (heater) during training.

There are various operational costs incurred other than for educational purposes, such as for cleaning up the equipment after use.

This system allows you to visually confirm how the film thickness changes when you operate the adjustment bolt in virtual space without using resin, making it a system that can be used for training new employees and as a tutorial on how to operate the system.

<Applying VR to equipment installation considerations/manuals>

<CASE 1: Verification of installation space when introducing equipment>

After the user decides to install the equipment, we create a 3D model of the equipment.

The modeled device is displayed in a virtual space at a 1:1 scale using VR goggles.

Using VR goggles, it is possible to project the installation space in three dimensions, making it possible to verify in advance whether there are any interferences with other spaces or structures, and whether the work flow is appropriate.

This allows you to predict the work that will occur after installation, improving work efficiency during equipment installation and enabling on-site response by predicting problems in advance.

Virtual space manual/operation training software

Modeling is done for the virtual space from the blueprint, and a familiar space like a game screen is depicted using software before the equipment is installed.

By using VR goggles, workers can enter a virtual space and experience the scale of the actual equipment, allowing them to intuitively learn information such as operation methods, safety training, maintenance manuals, and various consumable materials.

By intuitively checking the specifications of the equipment, we expect to improve the speed at which customers can learn how to operate the equipment when it is installed and reduce the incidence of accidents. We also aim to build a system that will enable both our company and the customer to share a VR screen and simultaneously view the same screen to remotely instruct on operation, point out maintenance points, share fault locations, and improve the accuracy of repairs and improvement guidance.

Development of NC processing robot technology

By combining robot arm technology with NC machining programs, we predict that in the future it will be possible to apply it to processes that could previously only be performed by humans (e.g., medical surgery).

We are developing CAM software for medical use, as we believe that in the future, when robotic arms become ultra-small, they will be applicable to medical applications.

Simulating surgery to remove cancer cells from the human spine

Processing test video

Modeling the spine skeleton

Setting the removal area (tumor)

We are engaged in long-term development that combines our mold processing technology, NC software development technology, and robot development technology, and we continue to take on the challenge of expanding into the medical and precision processing fields.

We have established a system that can meet the various needs of our users in the production of VR software and development of CAM software. Please feel free to contact us.

bottom of page