top of page

AX Molding Co., Ltd.

Specialized manufacturer of T-dies and feed blocks

We can handle a variety of applications, including high-precision thin film dies, sheet dies, and multi-layered products.

Tanzawa Techno Center (design, development, and manufacturing base)

0463-68-8223

FAX: 0463-57-8276

553-1 Soya, Hadano City, Kanagawa Prefecture, 257-0031

03-6424-7570

Head Office (Administrative and Accounting)

FAX 03-6424-4676

CINZA101, 2-8-2 Minami-Kamata, Ota-ku, Tokyo 144-0035

Reception hours: 8:30-17:30 (excluding weekends and holidays)

Lip Auto-Adjusting Die

<Automatic HEAT BOLT type die>

Typically, automatic lip dies measure the thickness of the formed film using non-contact measurement and feedback data to control the lip. This allows for minute lip movements, resulting in film products with high thickness accuracy. Heat bolt lip adjustment requires no clearance due to screw backlash or gaps caused by pushing or pulling parts. Adjustment hooks and other devices are designed to eliminate backlash at the connection points with parts through ingenuity. Thread backlash is also eliminated using hard lock nuts. Eliminating backlash in the pushing and pulling directions makes it possible to predict the lip position. Temperature control of heat bolts allows for precise adjustment. Temperature control can be achieved to within ±0.5°C, resulting in a minimum movement of 0.002 mm. The lip movement can be adjusted using a proprietary controller.

HB mechanical configuration

There are various types of HB dies available from different companies. We are constantly researching various HB shapes, hook shapes, adjustment screw positions, and other structures to create HB dies that are easy to handle.

<Verification of HB thermal expansion (elongation)>

Portable temperature control panel

Temperature and elongation graph

Dial Gauge

When adjusting the HB using the thermal expansion of metal, the length and installation angle of the HB that can be installed on the customer's equipment will vary depending on the space between the T-die and extruder and the roll arrangement during design.

When designing HB, we verify thermal expansion and then conduct a demonstration experiment to measure the elongation rate of the metal.

We convert the elongation rate calculated from past data and the elongation rate of the HB that has actually been designed into data, and verify how to reflect the data from the customer's film thickness meter to enable highly accurate control before delivering the product.

We also assist with the verification of existing equipment.

⭐️Motorized fully automatic T-die

Axe Molding has implemented the world's first "fully automatic motorized automatic HB die." This fully automatic die brings together the T-die technology we have cultivated over 20 years, machine tools, metal strength calculations (lip bending section), and control know-how.

1. Heat bolt adjustment (coarse adjustment) is remotely controlled by a motor

2. Quantitative management of lip clearance

3. Data collection of lip clearance for each product

4 ⭐️ Significantly reduced lip adjustment time (e.g., after reading data, adjustment time for a T2000 width die is within 10 seconds)

We have conducted extensive research and development based on hearings from users about issues they have had trouble with at manufacturing sites, and have now introduced this product to their production lines.

Reference photo (motor + HB type)

Overview structure diagram

HB pitch 22mm. Coarse adjustment of the four HBs is performed by a motor, and data from the film thickness gauge is reflected in the HBs, and the clearance is automatically adjusted using thermal expansion.

Self-adjusting die structure

Motorized adjustment bolt (coarse adjustment) + heat bolt (fine adjustment)

AXM patented technology

Motorized adjustment bolt (without HB)

AXM patented technology

We use a "motor control system" that minimizes changes in movement amount at T-die heating temperatures.

T360 Motorized Automatic HEAT BOLT Die

We have one in-house for testing purposes. It can also be used for narrow sheet testing (linked with a film thickness gauge).

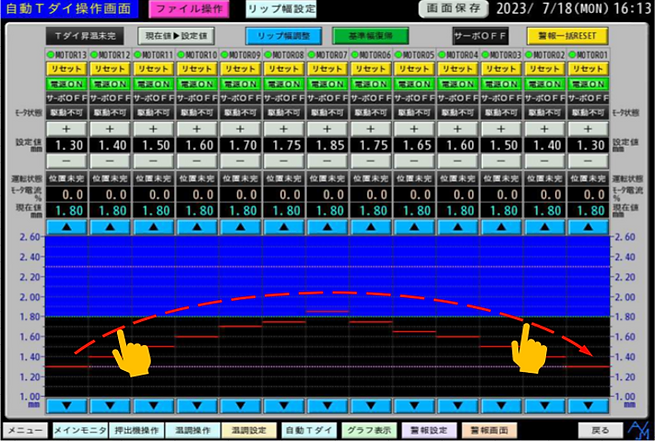

<Lip clearance automatic adjustment control device/operation panel (program developed in-house)>

Our software for multi-row motors calculates the difference between adjacent motors in the background to prevent torque increase between them, and when moving profiles simultaneously, it is not only possible to use the memory operation function, but also to program simultaneous operation so that profiles traced with a finger can be operated simultaneously.

Moving the motors instantly at the same time puts a strain on the CPU, so each operation is delayed by less than 0.1 seconds.

We have created a program that is designed to allow intuitive operation.

<Motor-driven fully automatic die>

For products that are not thin films but sheets (approximately 0.3mm to 2.0mm) or foaming sheets, where the thickness cannot be controlled by the slight thermal expansion of the heat bolt, we have developed a program that links the motor with a film thickness measuring device, allowing for automatic adjustment.

50mm pitch parallel arrangement

25mm pitch staggered arrangement

When adjusting only the motor, the pitch of the adjustment bolts tends to be wide, depending on the dimensions of the motor housing, but by arranging the motors in a staggered pattern, we have succeeded in narrowing the pitch to 25mm.By arranging the motors in a staggered pattern, the angle of the motor adjustment bolts can be adjusted at two different angles, and although there were high hurdles to overcome, such as the dimensions of the motor mounting part that adjusts the lip clearance (the amount of movement of each motor) and the creation of a program, we have succeeded in developing it using our unique know-how and mold processing technology.

<HB unit assembly considerations>

HB unit assembly

In order to bend the lip using a motor, we have made mechanical improvements and added many grooves (slits) near the hook attachment part of the lip bending section to make the lip more responsive and improve the HB's response.

The bending part is naturally designed by calculating the stress of the metal, taking into consideration the force applied when bending and the thermal stress at high temperatures, but the structure requires fine adjustments due to the thermal expansion of the HB, making it a very delicate part and extremely important for maintaining the precision of the film.

The HB hooks are fixed with bolts, and are assembled by tightening them evenly to the specified torque, but because the assembly is done by hand, slight differences will inevitably appear after assembly unless the dimensions are controlled.

After assembly, we use machining and a dial gauge to check the straightness of the lip, and then perform final fine adjustments to provide high-precision HB dies with good HB response.

<Motor + HB + inner/outer deckle die>

By attaching a deckle to a motorized HB die, the deckle can be operated either electrically or manually. It is possible to operate it fully automatically (remotely) and store the conditions. This greatly improves reproducibility when changing parts in mass production. If the deckle is also electrically operated, safety is also improved and the physical burden on on-site workers is significantly reduced. Our customers' on-site staff have praised it for being "safe and easy to operate."

<T660 Multi-Die (Interlocking Film Thickness Gauge) for R&D/Customer Testing>

A three-layer multi-T660 die was fabricated with a staggered motor unit of 25mm pitch attached to the front side and a heat bolt die with a motor attached to 8.5mm pitch attached to the back side.

Motor-driven side

(25mm pitch staggered arrangement)

Motor + HB type side

(Motor 50mm pitch/HB 8.5mm pitch)

Equipment photo

T660 Multi-Die Test Instrument

Main layer φ50 L/D 25

Satellite layer φ40 L/D 25 x 2 units

We are carrying out test molding using a 3-layer extruder + feed block + molding machine equipped with an automatic die.

If you provide us with the raw materials that will actually be mass-produced, and we can determine whether the adjustment method that best suits your needs is the motor + HB type or just motor adjustment, we have lab equipment that can be used to consider implementation, including film formation tests using our in-house equipment, training on operation methods, and mutual adjustment of adjustment programs.

Frequently heard voices from the production site

With operators aging and no middle-class talent, will there be technical successors in the future (10 years from now)?

Lip adjustment craftsmanship

Quantitative data on T-die operation techniques

When changing product types in small lots of various products

It is difficult to reduce work time loss

Want to eliminate dangerous work (manual lip adjustment during mass production)

(We want to secure operator personnel for the long term)

Extrusion molding sites are "high temperatures," "heavy T-dies and equipment (the molds are hot and it's easy to get burned)," "heavy labor," and "there are many rotating parts in the equipment, making it dangerous."

For those working on-site, such as those who work with sharp objects, there are many tasks that place a high mental and physical strain on the workers.

Our users' manufacturing site managers are concerned about securing human resources.

We believe that by quantifying technical data and promoting automation (remote control), it will be possible to create a safe and comfortable manufacturing environment.

Recently, we have received inquiries from many manufacturers for these reasons.

Regarding implementation, we have a system in place that allows us to promote development by listening to the voices of manufacturing sites as well as the technical needs of our customers.

Please feel free to contact us with any questions, even if they are small.

bottom of page