top of page

AX Molding Co., Ltd.

Specialized manufacturer of T-dies and feed blocks

We can handle a variety of applications, including high-precision thin film dies, sheet dies, and multi-layered products.

Tanzawa Techno Center (design, development, and manufacturing base)

0463-68-8223

FAX: 0463-57-8276

553-1 Soya, Hadano City, Kanagawa Prefecture, 257-0031

03-6424-7570

Head Office (Administrative and Accounting)

FAX 03-6424-4676

CINZA101, 2-8-2 Minami-Kamata, Ota-ku, Tokyo 144-0035

Reception hours: 8:30-17:30 (excluding weekends and holidays)

T-die accessories and auxiliary production equipment

We not only provide T-die peripheral equipment, but also auxiliary equipment required for product molding.

We handle everything from design to manufacturing. *We will introduce some of our achievements.

<T-die peripheral equipment>

T-die disassembly device (disassembly cart)

Vacuum chamber

<Molding peripheral equipment>

Screen changer

Gear pump

<Production equipment accessories>

○Liquid addition device

Crushing and separating machine

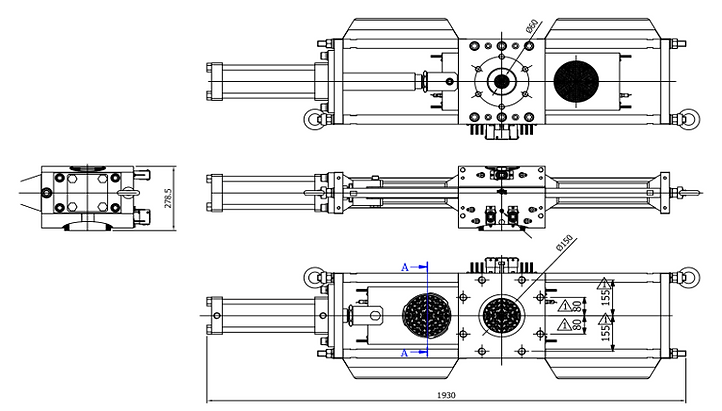

◯ T-die disassembly device (disassembly cart)

In order to stabilize and improve the quality of film and sheet, it is essential to periodically disassemble T-dies and clean the resin inside the flow passages. However, T-dies are heavy and are exposed to heat when disassembled, which is a heavy burden on workers. We offer a variety of disassembly equipment to improve work efficiency and enable safe and speedy T-die disassembly and cleaning work.

<Features>

1. Can be used with T-dies of various widths

2. Compatible with existing T-dies (requires addition of side plate parts to existing dies)

3 Speedy operation eliminates the need for reheating after removing the die (T-die can be opened within 30 minutes)

4. By using a reducer, excessive physical effort is not required, reducing the burden on the worker.

Wide T-die

Narrow T-die

◯ Vacuum chamber

Effect of the vacuum chamber

○Improved adhesion to cooling rolls

By drawing a vacuum, the air between the cooling roll and the resin sheet is removed. This allows the sheet to adhere tightly to the surface of the cooling roll, improving cooling efficiency. The surface precision of the cooling roll is faithfully reflected in the sheet, resulting in a beautiful, glossy surface. In addition, improved cooling performance makes it possible to increase the line speed, which is expected to increase production efficiency.

Vacuum chamber installation position diagram

◯ Screen changer

This is an essential device for removing foreign matter and impurities from molten polymer in the resin extrusion molding process, ensuring product quality.

<Flat screen changer>

1 Manual Screen Changer (Extrusion stops when changing)

2. Hydraulic automatic screen changer (extruder does not stop when changing filters)

The hydraulic automatic exchange system allows you to change the screen (filter) without stopping the extruder, minimizing downtime and material waste and improving production efficiency. Furthermore, by configuring a production line that combines an extruder with equipment such as a gear pump, you can achieve a high-precision melt filtration effect. This makes it possible to maintain a more uniform and high-quality finished product.

<Backwash type screen changer>

The backwash screen changer is used to filter dirty molten polymers that are likely to contain foreign matter such as recycled resins, and continuously removes impurities that have accumulated on the screen by backwashing (backflow cleaning) without stopping the equipment. Its main applications include the production of plastic pellets and film/sheets, where it purifies recycled raw materials, contributing to improved production efficiency and maintaining quality.

Features and benefits of backwash screen changer

Improved production efficiency through continuous operation:

The screens are backwashed automatically, allowing for continuous filtration and cleaning without stopping the production line.

Reduced filter replacement frequency:

The automatic backwash function efficiently removes impurities from the filter, reducing the frequency of manual filter replacement.

Reduced running costs:

Reducing the frequency of filter replacement reduces the running costs of the filters and the labor costs required for replacement.

Backwash type screen changer reference diagram

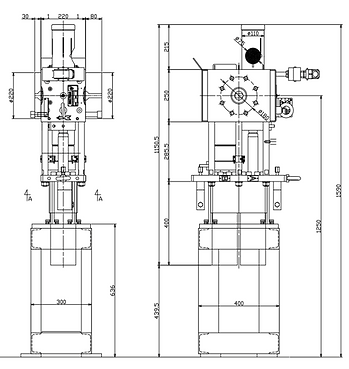

Gear pump

Gear pumps for resins are used to precisely deliver high-viscosity molten resin with a stable discharge volume and pressure.Their main application is in extrusion molding, where they offset pressure fluctuations from the extruder, improving the dimensional and shape accuracy of films and molded products, thereby contributing to improved product quality and a longer life for the extruder.

Pressure stabilization and precise delivery:

By offsetting pressure fluctuations from the extruder and accurately supplying a constant amount of molten resin, the precision of the dimensions and shape of the molded product is improved.

Improved product quality:

Stable discharge volume reduces product variation and improves quality.

Improved extruder performance and longer life:

It reduces extruder back pressure, increasing throughput and reducing strain on extruder components, extending extruder life.

Utilizing recycled resin:

This is effective because it allows a constant discharge rate to be maintained even when using a larger amount of recycled resin.

Discharge direction

worm reducer

Universal joint

gear pump

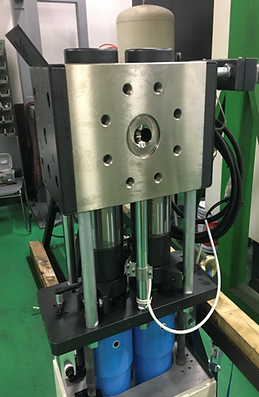

○Liquid addition device

Liquid addition in extruders is used to improve product properties by adding additives, lubricants, or reactants during the process. This can improve product quality or add new functionality in a variety of applications, including raw materials for antistatic agents, packaging films, automotive parts, and medical components.

Advantages of adding liquid

Uniform mixing:

Dispersing the liquid within the extruder ensures that additives are distributed evenly throughout the material, improving product quality.

Timing optimization:

Adding liquid at the right time during the process makes it easier to control reactivity and physical properties.

Applicable to a variety of materials:

By simultaneously extruding solid and liquid materials, it is possible to manufacture products with complex structures or multiple functions.

Regarding the method of addition, we provide equipment that is designed from various angles based on information such as the concentration of the added raw material, temperature requirements, and the pressure inside the cylinder on the extruder side.

Crushing and separating machine (for hoses and mats)

Crushing separators are used to crush materials into small pieces and also to separate and sort containers and their contents, different materials, etc.

This equipment crushes resin mats and resin hoses, which are formed by combining fibers such as glass fiber and paper with resin, and then separates the fibers from the resin, enabling the resin to be recycled.

Until now, recycling fiber-containing resin products through specialized companies has been expensive, but this equipment makes it possible to recycle them in-house at the customer's factory, resulting in reduced production and disposal costs.

○Pellet crushing and conveying equipment

A disintegrator is a device used to break down solidified lumps or chunks of powder or large raw materials into granules, and is used in a wide range of fields, such as for dehydrated cakes in the construction and mining industries, for sizing raw materials, and for eliminating clumps in packaging materials. Unlike a pulverizer, it does not break down materials into powder, but rather reduces them to a certain particle size before discharging them.

Main uses

Construction and mining:

Dehydrated cake (solids concentrated by filtration, etc.) is broken down and returned to granular form. It is used to remove foreign matter contained in building materials and mineral raw materials and to adjust the particle size to the required level.

Materials and Chemistry:

Particle agglomerates formed by aggregation of primary particles are loosened and dispersed without changing the size of the primary particles.

Our company has designers from various industries, not just the extrusion industry.

We also accept design requests for auxiliary equipment other than the main extrusion equipment.

"I want this kind of equipment, but I can't find a manufacturer that can provide it."

"The specifications of the manufacturer's standard products are insufficient, so we would like to add specifications when updating, but we cannot find a manufacturer that can accommodate this."

We are happy to answer any questions you may have, such as the above. Please feel free to contact us regarding additional equipment.

bottom of page