AX Molding Co., Ltd.

Specialized manufacturer of T-dies and feed blocks

We can handle a variety of applications, including high-precision thin film dies, sheet dies, and multi-layered products.

Tanzawa Techno Center (design, development, and manufacturing base)

0463-68-8223

FAX: 0463-57-8276

553-1 Soya, Hadano City, Kanagawa Prefecture, 257-0031

03-6424-7570

Head Office (Administrative and Accounting)

FAX 03-6424-4676

CINZA101, 2-8-2 Minami-Kamata, Ota-ku, Tokyo 144-0035

Reception hours: 8:30-17:30 (excluding weekends and holidays)

It's now in operation!

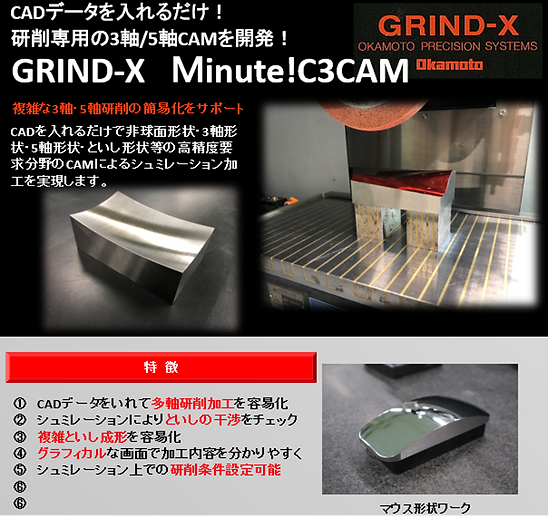

<New equipment introduction> OKAMOTO CNC ultra-precision surface grinding machine

Grinding length: 2 meters

Vibration-free thanks to linear motor drive and high-precision oil static pressure mechanism. Comes with "MAP Ken" software. High-precision polishing of curved surfaces is possible!

We are the only company in Kanagawa Prefecture that has introduced this machine. It is the No. 1 precision surface grinding machine.

< Intention/purpose of introduction>

In most cases, the lip land of the T-die is plated.

When used for a long period of time, the lip will wear and slight distortions and deformations will occur on the adjustment bolt side, which will cause variations in film thickness, especially when producing films with high film thickness precision.

Usually, to restore accuracy,

Plating removal → Lip land re-polishing → Seal surface polishing → Inlay processing → Re-plating → Finishing

This process requires a lot of time and money.

This device "controls the movement of the polishing stone in the Z direction."

It is possible (MAP Research Institute)

This allows polishing only the areas where the film-like irregularities are present.

Process: Mapping of grinding surface → Setting of grinding amount → Polishing only necessary areas → Surface finishing (hand polishing)

Even without stripping and re-plating, by using MAP grinding software to grind only the areas with defective film thickness, we can contribute to reducing lead time and costs for repairs.

CAD models

Automatic calculation of coordinate data

Automatic on-machine measurement

Automatic workpiece shape generation

The latest system brings about a revolution in grinding: "MAP grinding"

MAP polishing achieves high-precision grinding without skill/automation

When CAD data is input, the workpiece is automatically measured and the optimal grinding program is automatically generated/processed.

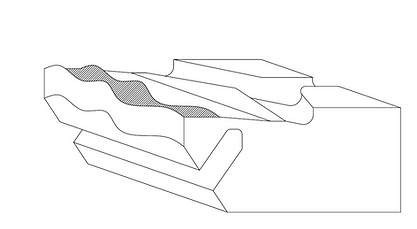

Lip distortion (image)

Grinding direction of grinding wheel

Sensor measurement (mapping)

grindstone

After mapping

Grinding necessary areas by program

STEP 1: Lip distortion is automatically measured by mapping and converted into data.

STEP 2: Specify the lip area you want to grind from the data. Specify the grinding amount numerically.

*The grinding location and grinding amount of the T-die are specified based on the customer's film thickness data.

Where our know-how is most important

STEP 3 Measure the amount of grinding and plating thickness to determine whether or not it bites into the base material.

STEP 4 Grind the necessary areas. Remeasure after grinding.

Equipment installation scene

The extrusion molding test building at Tanzawa Techno Center was renovated.

October 12, 2025 Equipment delivery

End of October 2025 Grinding equipment operation test

November 1, 2025: We will start accepting orders for grinding processing!