top of page

AX Molding Co., Ltd.

Specialized manufacturer of T-dies and feed blocks

We can handle a variety of applications, including high-precision thin film dies, sheet dies, and multi-layered products.

Tanzawa Techno Center (design, development, and manufacturing base)

0463-68-8223

FAX: 0463-57-8276

553-1 Soya, Hadano City, Kanagawa Prefecture, 257-0031

03-6424-7570

Head Office (Administrative and Accounting)

FAX 03-6424-4676

CINZA101, 2-8-2 Minami-Kamata, Ota-ku, Tokyo 144-0035

Reception hours: 8:30-17:30 (excluding weekends and holidays)

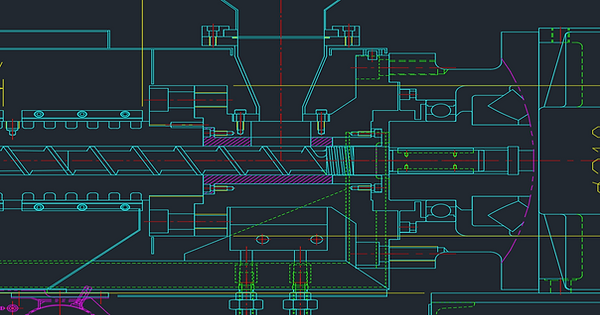

Special FILM Molding Machine

At AXM, we not only manufacture T-dies, but also extruders, roll forming machines, and T-die accessories.

We also sell complete film equipment. Decide on the line configuration that matches your desired resin,

The key factor is to consider whether or not you want to enter that space.

We design and manufacture customized equipment ranging from small research applications to multi-layer, medium-sized and large-sized film equipment.

We can also produce products with short delivery times, so please consider this.

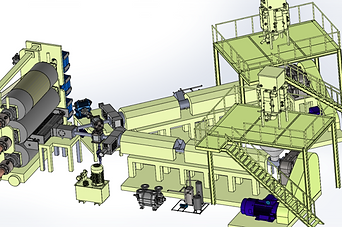

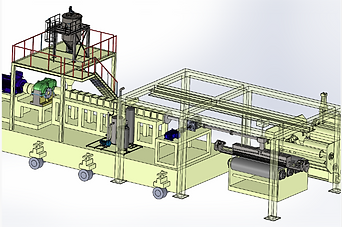

We can handle widths ranging from 150mm to medium-sized 1000mm and large-sized 4000mm, including extruders, T-dies, gateposts, roll forming machines, film thickness gauges, defect inspection machines, and winding machines.

Achievements: CPP, SPVC, ABS, Fluorine, PPS, PEEK, LCP, TPU, PC, PMMA, COP, PET, NY, etc.

Especially for multi-layer films, we are particular about the extruder layout that makes the most of AXM's unique feed block and multi-manifold mold features, and the layout of the gatepost for T-die installation. The gatepost is designed so that T-dies can be easily installed and can be cleaned on the machine. We can propose film and sheet forming equipment that is easy to use and has high productivity from various perspectives.

We can meet your needs, whether it's specifications tailored to the price, production in a short period of time, or specializing in high precision.

3-layer medium-sized sheet forming device 1000mm wide

4 types 7 layers medium size film forming device 600mm wide

2-type 3-layer large sheet forming device 1500mm wide

Laminated single layer sheet forming machine 2500mm wide

Twin-screw extruder mounted on a movable stand

<Steps to introducing the device>

flow

Approximately 1.5 months

Current situation analysis

Specification finalized

Work content

Current situation analysis

Basic concept design

Check the specifications

About 1 month

Main design

Submission of approved drawings

Specification submission

Approximately 5 months

Manufacturing/processing

Equipment parts processing

Electrical Design

About 1 month

About 1 month

Assembly and wiring

Testing and installation

Device assembly

Electrical wiring

Final specification confirmation

Adjustment of delivery schedule

Installation and implementation support

Approximately 0.5 months

Molding evaluation

Checking for assignments

Collaboration with customers

Meeting with the coordinating department Confirm product requirements, uses, and specifications Meeting with the production department to schedule

Approval of drawings and specifications Process meeting (once a month)

Checking customer utilities

Rechecking the specifications

Check how it works

Witness test

Delivery route confirmed

Schedule adjustment

Product Evaluation

Start of operation

Implementation completed in approximately 10 months

Case studies

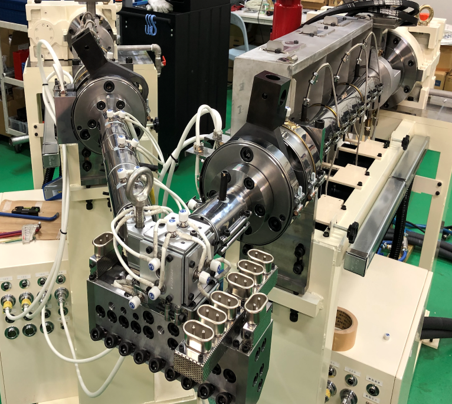

2-type 3-layer (2-type 2-layer) Combi small laboratory extrusion molding line

For laboratory use: φ35/φ30, 2 types, 2 layers, (*) ultra-compact FB, T-die, roll forming equipment (with cooling blower).Using the ultra-compact FB, we can install a space-saving laboratory multi-layer equipment.We will also solve your worries about installation space.

<3 types, 3 layers (5 layers)> Laminating extrusion line

We have added a multi-layer laminating machine next to the single layer laminating machine.

We have created a FB that can also be used for multi-layer applications, making it a universally usable facility.

<Twin-screw extruder + T1700 die large coater line>

We overhauled the customer's idle equipment, connected the FB, SC, and GB, installed a large deckle die, and used it as a new line, successfully expanding the facility while keeping initial costs down.

<φ135-35V single-screw extrusion sheet molding line>

We have added a new extruder to our single-layer PS sheet (thick) molding line and remodeled it into a line capable of producing multi-layer sheets. We have newly installed GP, SC, and FB, and have successfully operated it as a production line that can switch between single-layer and multi-layer on one line.

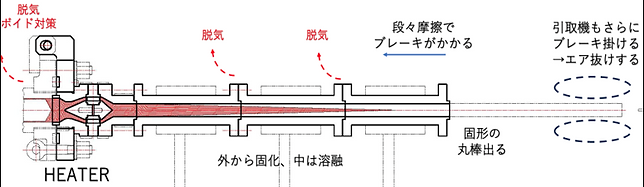

Sheet forming line for thick plate forming (solidification forming line)

This line uses an extruder to mold thick plates, a very unique molding method. Thick plates (thickness: 20mm to 150mm) with widths up to 1200mm can be molded.

The principle of molding is different from thin film or sheet molding. Since thick plates are slowly molded while being extruded, unique know-how is required for methods of removing internal stress during cooling, cooling times, and other techniques.

Special attention to detail under the hopper

It is essential to design the bottom of the hopper to have grooves that forcefully propel the pellets forward, thereby suppressing the generation of voids during molding. The relationship between the screw shape and groove shape requires a great deal of know-how.

For film and sheet equipment, we predict the roll path line while taking into consideration the characteristics of the resin and the thickness of the film. The path line is largely determined by experience. When designing, we propose a path line by combining our proposals with the customer's experience. When we receive an inquiry, we will submit a drawing before providing a quote, and we will revise the image several times as we put together a quote. The production period is approximately six months to one year. Please consider our film equipment.

bottom of page