top of page

AX Molding Co., Ltd.

Specialized manufacturer of T-dies and feed blocks

We can handle a variety of applications, including high-precision thin film dies, sheet dies, and multi-layered products.

Tanzawa Techno Center (design, development, and manufacturing base)

0463-68-8223

FAX: 0463-57-8276

553-1 Soya, Hadano City, Kanagawa Prefecture, 257-0031

03-6424-7570

Head Office (Administrative and Accounting)

FAX 03-6424-4676

CINZA101, 2-8-2 Minami-Kamata, Ota-ku, Tokyo 144-0035

Reception hours: 8:30-17:30 (excluding weekends and holidays)

Dickeldie

<Dickel Die>

The width of the lip of a T-die is fixed, but by using a deckle, the lip width of the T-die can be changed.

This reduces the amount of ear cropping required.

The main features of Dickel are

1. Outer deckle die

2. Inner deckle die

3. It is necessary to design the die to suit the full width, resin viscosity, and film or sheet application.

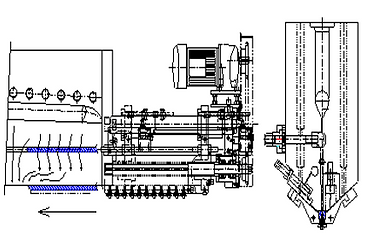

<Outer deckle type T die (reference drawing)>

Outer deckle...(see diagram)

An outer deckle has a baffle plate placed at the lip exit. Because it is a lip exit, a large amount of pressure is applied inside the resin, so a rigid frame is attached at both ends, making it possible to slide it on the lip. There are also models that can be moved by simply turning a handle using a screw, and electric models that use a gear motor.

This is a type in which a slide plate is attached to a trapezoidal screw nut and the gear motor is chain-driven to move it.

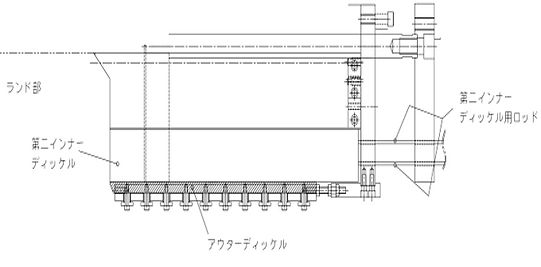

<Inner deckle (round bar insertion type)>

Inner deckle...(see diagram)

The inner deckle is used in conjunction with the outer deckle. Rather than the outer deckle receiving pressure from the lip outlet, the inner deckle's round rod placed inside the manifold can reduce resin pressure. This means that the deckle can be operated during operation. The presence of the inner deckle makes it possible to change the width even during operation.

*However, this outer and inner deckle structure has the disadvantage that the resistor is inserted at a right angle to the resin flow surface, which creates areas where the resin stagnates and causes resin burning.

Inner and outer deckle

<Full width deckle>

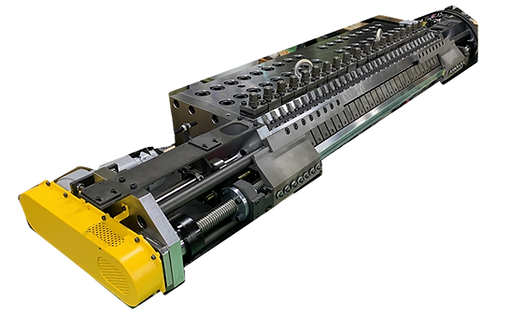

Full width deckle...(see diagram)

The full-width deckle enables molding of resin that would otherwise be unusable due to burnt resin retention, and the entire manifold can be moved as a deckle. The full-width deckle moves the manifold by sliding it, but since it is the sliding part that stops the resin, high processing precision and technology are required to prevent resin leakage, and we have a considerable number of units in this field. We can also manufacture full-width deckles with choke bars.

This is an example using a screw jack with an electric motor. The full-width deckle requires a high thrust because it is affected by the internal resin pressure.

<Laminating die (with deckle)>

This is a T-die that attaches resin to the main sheet or film.

T-die for sandwiched lamination...(see diagram)

Resin is placed between two unwound sheets of nonwoven fabric or glass fiber. The T-die must meet various requirements, such as a sharp tip to fit between the two sheets, and a lip adjustment bolt that can be adjusted to a longer length. Thickness accuracy tends not to be required. A notable feature is that many T-dies have deckles to adjust the sheet width.

Features of deckle for laminate

The inner deckle rod is attached to the side plate as a guide at the die lip, and a thin inner deckle plate is attached to the die lip. Because of the simple concept, even if the inner deckle plate is damaged, it can be easily replaced.

A wide variety of deckle structures are available, from thick sheets to film lamination and coating dies.

We also undertake the design of T-dies. In addition to new T-dies, we also undertake the overhaul of existing dies.

We can handle even small matters. Please feel free to contact us.

bottom of page