top of page

AX Molding Co., Ltd.

Specialized manufacturer of T-dies and feed blocks

We can handle a variety of applications, including high-precision thin film dies, sheet dies, and multi-layered products.

Tanzawa Techno Center (design, development, and manufacturing base)

0463-68-8223

FAX: 0463-57-8276

553-1 Soya, Hadano City, Kanagawa Prefecture, 257-0031

03-6424-7570

Head Office (Administrative and Accounting)

FAX 03-6424-4676

CINZA101, 2-8-2 Minami-Kamata, Ota-ku, Tokyo 144-0035

Reception hours: 8:30-17:30 (excluding weekends and holidays)

T-die feedblock maintenance/overhaul

⭕️Please feel free to contact us in such cases.

The accuracy of the film thickness has worsened since the introduction

I scratched the T-die lip

The body bolts cannot be removed and the unit cannot be disassembled.

There are streaks on the film/sheet and I want to fix it.

Production cannot be stopped for long periods of time

I want an emergency response

We can handle any T-dies for resin extrusion molding (products made by other companies).

⭕️T-die maintenance details

Special technology AX-Process

*This is a unique skill possessed by only two people in the world, in which only the damaged areas are padded and plated.

・We can handle the process on-site without transporting the T-die! Correction can be completed in as little as one day.

It can also be applied to feed blocks. We can also visit overseas bases to provide support!

STEP 1 Diagnosis

STEP 2: Filling in the wound

STEP 3 Flat surface

STEP 4 Partial plating

STEP 5 Final Finishing

⭕️Plan Description

remarks

1. Each plan is compatible with a wide range of die types, including straight manifold dies, coat hanger dies, deckle dies, and various feed blocks.

2. Plan OH delivery times may vary depending on the die size. Please contact us for details.

3. Please provide a separate quote for special specification dies.

4. When you inquire, please provide us with a photo, the exterior dimensions, and the name of the plan you would like.

5. Please arrange for the packaging materials to be used when transporting the product to our company. The cost of delivery and return shipping will be borne by the customer.

We also provide maintenance for peripheral equipment, extruders, and control panels other than T-die Ford Blocks! Please feel free to contact us!

<Maintenance example 1>

⚫︎T 3800 multi-die. It has been in continuous production for over 10 years and has never broken (bolt stuck).

⚫︎There seems to be a scratch on the lip, and the die line won't disappear. ⚫︎Resin is leaking from the side plate area.

We will handle this using our "Plan Pro AX-Process"

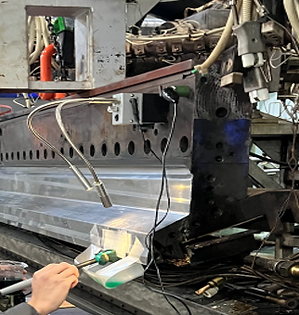

The bolt is stuck (M36), and even with a 4000N power wrench, the hexagon breaks and the bolt won't loosen (the die can't be disassembled).

Using a very special technique to remove the bolt

(The bolt can be removed without breaking.)

Turn it over, disassemble and clean the resin

Chipped and damaged lip plating is done on-site using the AX-Process

The adjustment side is installed in a gate-type configuration during assembly and restoration, and then plated on site.

Restoration installation work and parallel alignment

Restoration and resin removal completed

<Maintenance example 2>

⚫︎ I want to do a full overhaul of the T1800 die.

⚫︎ The die itself may be distorted due to aging.

⚫︎ I would like the flow path to be deplated and polished.

After disassembly, we inspected the straightness and found distortion. We adjusted the overall distortion by machine.

Check the straightness again after adjustment. Record any minute distortion. Decide the area to polish.

After determining the amount to be removed with the grinding machine, grind the seal surface and lip land.

After processing is complete: ⚫︎Re-plating of flow passages ⚫︎Finishing of lip edges after plating ⚫︎Re-measuring straightness ⚫︎Assembly (restoring adjustment bolts and heaters)

⚫︎Inspection attendance

Even T-dies that have deteriorated over time can be restored to new condition with appropriate processing.

Lip part is polished

The φ part of the inlay and the flow path entrance part are also machined by the amount of polishing of the seal surface.

<Case 3>

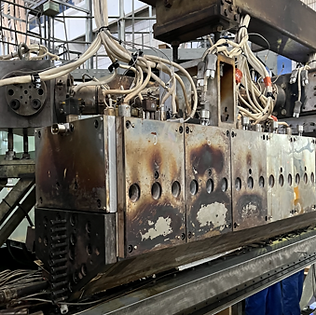

Extruder (two-screw) production line

⚫︎2200mm wide sheet forming line ⚫︎It is imported equipment and there is no one to ask for maintenance ⚫︎There seems to be a problem with the feed pipe, but it has never been disassembled.

⚫︎When the equipment is restarted after being shut down, it takes a considerable amount of time (approximately 3 days with 24-hour operation) for the black spots on the sheet to disappear.

After inspecting the device, disassembly is carried out.

When disassembling heavy objects, the bolts must be loosened and removed while the object is still hot, as the installation balance must be taken into consideration and resin is contained inside.

We disassemble other companies' machines based on careful planning, safe work practices, and experience.

Our company has staff who are designers and can also handle heavy work, so rather than simply carrying out heavy work, we work by predicting the structure of the extruder to a certain extent and focusing on its weak points.

Maintenance support (disassembly and cleaning)

At our company, a designer always accompanies the work and works together with the weight specialist to make improvements. We have established a system in which weight work can proceed from the design side's perspective (our weight subcontractors act in accordance with the design side's opinions).

Any defects found on-site will be reported to the customer and, after obtaining their approval, we will carry out the necessary improvements and processing, all within a flexible and limited work schedule.

(If the part is located near the Kanto region, we will bring it back to our company, perform machining immediately, and complete the improvement work within the construction period set by the customer.)

This is possible because our designers accompany the on-site work, sketch on-site, draw up additional work drawings, and we have NC processing machines in-house, which allows us to respond quickly in a unique way.

We are confident in our speedy response!

We handle a wide range of services, from relocating equipment within a customer's premises to relocating equipment to distant locations or to overseas bases.

We provide one-stop solutions to concerns such as "It's far away..." or "It's difficult to coordinate with contractors..."

When relocating, we can also flexibly modify and improve equipment, which is one of our strengths (maintenance of equipment and T-dies during the relocation period, arranging parts, and replacement and adjustment at the time of installation).We will utilize our strengths in design and development in a variety of ways to support our customers' manufacturing activities.

bottom of page