top of page

AX Molding Co., Ltd.

Specialized manufacturer of T-dies and feed blocks

We can handle a variety of applications, including high-precision thin film dies, sheet dies, and multi-layered products.

Tanzawa Techno Center (design, development, and manufacturing base)

0463-68-8223

FAX: 0463-57-8276

553-1 Soya, Hadano City, Kanagawa Prefecture, 257-0031

03-6424-7570

Head Office (Administrative and Accounting)

FAX 03-6424-4676

CINZA101, 2-8-2 Minami-Kamata, Ota-ku, Tokyo 144-0035

Reception hours: 8:30-17:30 (excluding weekends and holidays)

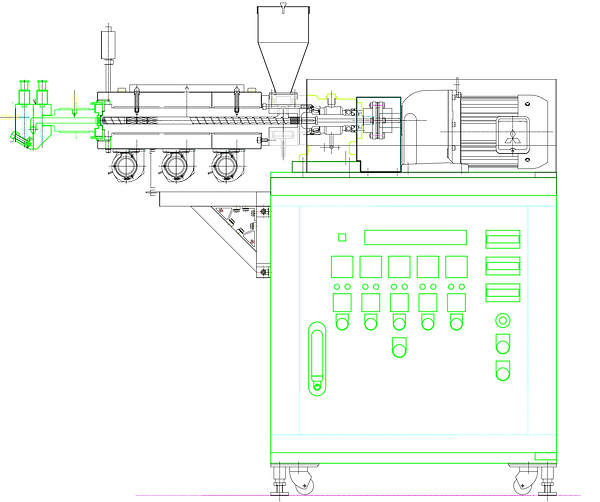

Special extruder

SIZE : Φ12~150mm

・Lifting type extruder

・L/D=36 or more extruder

・Water-cooled type extruder

・Extruder for foaming (gas injection, tandem, etc.)

・pair, tandem, triple extruder

・Small diameter extruder (Φ12~20mm)

・Extruder for fluorine(abrasion-resistant&anticorrosion HIPcylinder)

・Extruder for recycle

・Extruder for R&D(many pressure gage, with visualization window, with data logger)

・2-axis extruder, gear pump stand, feeder stand

Extruder peripheral equipment here

<φ12-L/D24 extrusion device>

This is a small 12mm extrusion molding device. ⚫︎ Output: 400g/h (specific gravity: 1)

⚫︎For extrusion molding of small diameter tubes, etc. ⚫︎For sheeting of developed materials (low discharge, resulting in less loss)

<φ20-L/D24 extrusion device>

φ20 small extrusion molding machine for tube and small sheet testing

<φ25-L/D26 extrusion device>

It is a small 25mm extrusion molding device.

Discharge rate: 10 kg/h (specific gravity: 1)

For extrusion molding of small diameter tubes, etc.

⚫︎For molding electrical wire coating applications

Medium-sized extruder A line for molding evaluation samples

φ35-L/D 25 single screw extruder

φ50-L/D25 Single-screw extruder (with SC)

<Lifting type extruder> φ40 single screw extruder

This device allows you to change the extruder's core height. A lifting mechanism is attached to the extruder frame, allowing for adjustment. ⚫︎ Extruder for solidifying thick materials

⚫︎Satellite extruder for multi-layer molding equipment

⚫︎Other special uses

Medium to large size extrusion equipment

Extruder with a high output capacity that can handle wide T-dies. Ideal for film molding lines/multi-layer film molding lines.

φ65-L/D28 Low-floor rail front-rear movement single-screw extruder

φ90-L/D 24 Independent back and forth moving extruder

<Vent-type vacuum device>

By opening a degassing port in the extruder cylinder and using a vacuum pump to remove the gas generated inside the cylinder during heating, it is possible to prevent air bubbles from entering the film or sheet extruded from the T-die and to produce beautiful film or sheet without a resin pre-drying process.

The degassing part design is packed with know-how

Vent screw (φ125 L/D 33 1V)

Regarding the intake and exhaust system,

We have the design know-how.

⚫︎Dry vacuum pump (factory pollution prevention)

⚫︎Selection of oligomer filter ⚫︎Countermeasures against unpleasant odors after degassing ⚫︎Filter replacement system during continuous molding

We provide systems tailored to user needs.

<Fluorine extruder>

Fluorine resins have a much higher melting point than olefin-based resins, so they require molding at much higher temperatures. High-output heaters (cast brass heaters) are also required. Furthermore, because fluorine generates corrosive gases when melted, the metal material inside the resin flow path and cylinder will rust if used in a standard extruder (SCM 440). Therefore, special specifications using corrosion-resistant Hastelloy material are essential.

Reference photo

Reference diagram

Generally, fluorine cylinders are coated with corrosion-resistant alloys on the inner diameter, injection end face, and hopper mouth, and other parts are nickel-plated or similar. However, in more adverse environmental conditions, cylinders must be manufactured entirely from Hastelloy. Using all Hastelloy makes handling difficult due to the high material and processing costs, and the biggest problem is that the cylinders are large in size, making it difficult to obtain the raw material itself. We can solve this problem with Hastelloy by using multi-layer HIP.

<Fluorine φ35 extruder>

⚫︎Fluorine resin compatible, high temperature 450℃ specification

⚫︎Cylinder screw is corrosion-resistant C276 equivalent Screw is a rapid compression screw

⚫︎Can also be used with high-temperature resins other than fluorine

Fluorine extruders are packed with highly confidential know-how.

We will refrain from disclosing any documents on our website, but please feel free to contact us if you have any problems or concerns.

Screw design and motor selection

Extruders available on the market have a wide variety of screw shapes depending on the resin and discharge characteristics.

With over 20 years of testing and implementation experience, we can propose the optimal screw based on resin data, and have the technical capabilities to improve various phenomena such as improving discharge volume and pulsation.

Screw shape (partial excerpt)

Screw geometry and extrusion rate calculation

We calculate the extrusion volume based on the resin used by the customer and the desired production volume, and select the motor after taking into consideration the screw outer diameter setting, compression ratio, and configuration. By selecting the appropriate motor output, we can propose an extrusion device that can be operated in an energy-efficient manner.

We also have a wealth of experience and know-how in screw design.

We can also handle improvements to existing equipment and new designs. Please feel free to contact us!

bottom of page