top of page

AX Molding Co., Ltd.

Specialized manufacturer of T-dies and feed blocks

We can handle a variety of applications, including high-precision thin film dies, sheet dies, and multi-layered products.

Tanzawa Techno Center (design, development, and manufacturing base)

0463-68-8223

FAX: 0463-57-8276

553-1 Soya, Hadano City, Kanagawa Prefecture, 257-0031

03-6424-7570

Head Office (Administrative and Accounting)

FAX 03-6424-4676

CINZA101, 2-8-2 Minami-Kamata, Ota-ku, Tokyo 144-0035

Reception hours: 8:30-17:30 (excluding weekends and holidays)

machining equipment

.png)

Our company has staff with experience in machine tool design, so we can rework used equipment and restore it as T-die processing equipment.

This reduces in-house processing costs and enables us to respond to processing speeds.

Okuma NC milling machine (vertical) MC-5VA

Table size 1550 x 650

Spindle speed: 4000 rpm

Stroke X1050 Y 510 Z 560

It has power and excellent bite.

Machining of T-die workpieces Machining of feed blocks

Active in processing T-die accessories

Makino Vertical NC Milling Machine FD 106

Table size 1400 x 600

Spindle speed: 3500 rpm

Stroke X1050 Y600 Z560

This one also has excellent bite!

Currently being used extensively in parts processing

Yamazaki Giken General-Purpose Milling Cutter YZ-8

Table size 1400 x 380

Spindle speed 75-2400 rpm

Stroke X850×Y400×Z550

Great for machining small parts and T-die accessories. Comes with guidance that does not require NC programming, allowing for quick machining.

Makino Vertical NC Milling Machine MS-50

Table dimensions: 800 x 500

Stroke X600×Y500×Z400

Spindle speed: 60-6000 rpm

It rotates at high speed, so it is also used for finishing parts. It is small, easy to handle, and has a fast setup speed, making it useful for speedy processing.

Yoshida Radial Drilling Machine YR3-115

Spindle speed: 1800 rpm

Table 800×800×400

This single machine can perform drilling, large diameter tapping, and other operations, and can process deep holes and taps with T-dies and FBs at a considerable speed.

Yamazaki Mazak VTC-200C

Table size 2300 x 510

Stroke X1950 Y510 Z510

Spindle speed: 10,000 rpm

High-precision machining center

It is used for processing T-die manifolds.

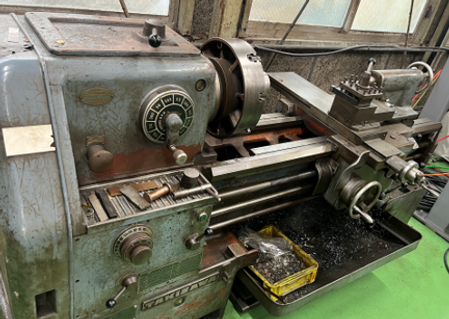

TAKIZAWA general-purpose lathe

It is currently being used for machining cylindrical necks and small parts, and is a general-purpose tool that can be used immediately after setup and centering.

We also handle parts repairs.

NAGASE polishing machine

T-die lip polishing

FB facing

It is useful for adjusting dimensions after T-die FB processing.

We also handle parts repairs, additional work, and fee-based processing. We are confident in our response speed. We look forward to hearing from you.

Metal 3D printer

[Installation of metal 3D printer]

Until now, multi-layer molds have only been assembled by machining,

Metal 3D printers can produce one-piece parts in a short amount of time.

Your 3D designs can be brought to life, allowing you to create a variety of extrusion parts beyond your imagination.

If you provide us with a 3D model, we can produce any part.

Metal 3D printer

Extrusion mold production is performed using a metal 3D printer, Sodick LPM325S.

・Super multi-layer tube (balisong)

・For ultra-multilayer films ・Partial multilayer films ・Lumen tubes ・Hastelloy materials are also available

Mold making video

[Exploring new possibilities with metal 3D printer processing]

・Two types of 20-layer super multi-layer tube die (patent pending)

A extrusion

B extrusion

ABABAB...

[Example of processing using the AXM additive technology metal 3D printer]

Curved neck

Lumen tube air hole

Ultra-multilayer FB flow channel model

Production Examples: In order to realize ultra-multilayer flow channels, it is possible to test-try shapes that cannot be produced by cutting using a 3D printer, reducing the initial cost and time required for molding tests.

bottom of page