top of page

AX Molding Co., Ltd.

Specialized manufacturer of T-dies and feed blocks

We can handle a variety of applications, including high-precision thin film dies, sheet dies, and multi-layered products.

Tanzawa Techno Center (design, development, and manufacturing base)

0463-68-8223

FAX: 0463-57-8276

553-1 Soya, Hadano City, Kanagawa Prefecture, 257-0031

03-6424-7570

Head Office (Administrative and Accounting)

FAX 03-6424-4676

CINZA101, 2-8-2 Minami-Kamata, Ota-ku, Tokyo 144-0035

Reception hours: 8:30-17:30 (excluding weekends and holidays)

List of technologies and terms

2. Different adjustment bolt shapes

6. Extrusion volume (effect of rotation speed)

7. Extrusion volume (effect of metering groove depth)

8. Extrusion volume (effect of cylinder diameter)

9. Extrusion volume and drawing ratio

10. How to express screw shape

11. Screw compression ratio guideline

12. Screw compression section length guideline

01

What is an adjustment bolt?

The tip of the die is made flexible and acts as an adjustment bolt for adjusting the gap in the flow path.

This allows precise adjustment of thickness distribution across the width without disturbing the flow of the molten resin.

Bending type adjustment bolt

The T-die body is provided with a groove that allows it to be bent, and by pressing it with a bolt, the opening of the lip can be adjusted.

The distance between the groove and the flow path (thickness of the die body) is set to make it easy to adjust the opening.

It becomes important.

The thinner the material, the easier it is to bend, but if stress is applied that exceeds the yield point of the metal material, the bend will not return to its original shape.

The bending lip is designed with stress in mind.

The differential screw structure of the adjustment bolt utilizes the difference in pitch between the two screws to perform minute feeds.

(Example) P2.5 - P2.0 = 0.5P The movement amount is only 0.5 mm per rotation.

02

Regarding different adjustment bolt shapes

Typical shapes and features of lip adjustment bolts

①Bolt type

This is a shape used in many film dies.

Features

- The pitch between adjacent bolts can be narrowed.

・Differential screw pitch can be made finer.

-When you adjust it by pressing it at a point, the change in the lip is clearly visible.

→The advantage is that the lip opening is easy to adjust.

② Hook type differential screw

It is often used in sheet dies.

Features

- The hooks on the die body are replaceable.

· Because it is pressed on a flat surface, there is little difference in bending between adjacent bolts.

This allows for smooth lip changes.

03

Special adjustment bolts

① Hook bolt

By changing the angle, it can move up to 2mm.

② General-purpose bolt additional processing

The tip can be fixed and pushed/pulled.

04

What is a replacement lip?

By replacing the lip at the tip of the die, the lip gap can be changed to a larger specification. This has the advantages of being quick and large, but also has the disadvantage of causing a step in the flow path, which can lead to stagnation.

05

Chalk Bar

The choke bar is located in the intermediate flow path between the manifold and the lip.

This bar adjusts the restriction after the manifold to control the flow rate.

Chalk bar structure

Unlike the lip adjustment bolt, the choke bar is not a differential structure.

The nut rotates counterclockwise to tighten the choke bar.

It is the opposite of the lip adjustment bolt.

Chalk Bar

06

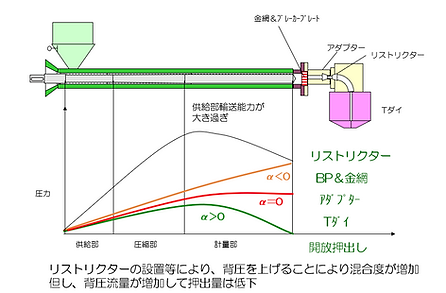

Extrusion volume (effect of rotation speed)

The propellant flow rate increases in proportion to the screw rotation speed.

However, as the extrusion rate increases, die pressure loss increases and back pressure flow rate increases.

The actual flow rate decreases.

.png)

07

Extrusion volume (effect of metering groove depth)

.png)

The propulsion flow rate increases in proportion to the depth of the metering groove.

On the other hand, the back pressure flow rate increases in proportion to the cube of the metering groove depth.

If the groove depth is made too deep, the actual flow rate will decrease.

Furthermore, if the groove depth is increased, the degree of mixing will deteriorate, so careful attention must be paid to this.

08

Extrusion volume (effect of cylinder diameter)

When actually scaling up, it is necessary to consider the shear and heat transfer of the resin.

Since groove depth and screw rotation speed are changed, it is not a square,

It increases by a factor of 2-2.5.

*It can be roughly calculated simply by multiplying it by 2.1.

.png)

.png)

09

Extrusion volume and drawing ratio

10

How to express screw shape

11

Screw compression ratio guideline

12

Screw compression section length guideline

13

Effect of screw groove depth

14

Screw shear heat

bottom of page